Specialty Fitters, Inc. - Mechanical Division

Over 35 Years of Experience

With over 35 years of experience in the industrial gas industry, servicing the major gas companies and large corporations, Specialty Fitters, Inc. has a deep understanding of the sector's intricacies and nuances. Our extensive knowledge and expertise allow us to provide tailored solutions to meet our diverse range of clients' specific needs and unique requirements, ensuring utmost satisfaction and efficiency.

High Purity Process Piping Systems & Tubing

At Specialty Fitters, Inc., we specialize in delivering high-quality high-purity process piping systems for a wide range of industries. Our extensive experience and expertise ensure that our systems meet the most stringent requirements for purity, cleanliness, and reliability.

Our high-purity process piping systems are designed to meet the exacting standards of industries such as pharmaceuticals, biotechnology, food and beverage, and semiconductors. We use only the highest quality materials and components to ensure the integrity of your processes and the purity of your products.

With Specialty Fitters Inc., you can trust that your high-purity process piping system will be custom-designed to fit your unique needs and specifications. Our team of skilled engineers and technicians will work closely with you to develop a solution that meets all of your requirements and exceeds your expectations.

Cryogenic Systems

At Specialty Fitters, Inc., we specialize in the installation and maintenance of cryogenic gas systems. These systems are used in various industries to store and transport gases at extremely low temperatures.

Our team of experts is well-versed in the intricacies of cryogenic gas systems, ensuring that installations are carried out efficiently and with the highest level of precision. We also offer tailored maintenance programs to ensure that your system operates at peak performance at all times.

Whether you are looking to install a new cryogenic gas system or need maintenance for an existing one, you can rely on Specialty Fitters Inc. for quality service and expertise. Contact us today to learn more about how we can assist with your cryogenic gas system needs.Vacuum-jacketed cryogenic distribution systems. Servicing all phases from concept, design, fabrication, and installation for liquid cryogenic applications

Maximizing product conservation and profitability with state-of-the-art frost free vacuum insulated piping

Servicing systems requiring fixed and portable liquid cryogen storage, bulk tank storage, vaporizers, pressure control manifolds, and customer use stations

Designing and building skidded systems

Repairing and rebuilding cryogenic tanks, tubes, and equipment

Testing and certification

Cost analysis of current system vs. new vacuum-jacketed system with payback documentation

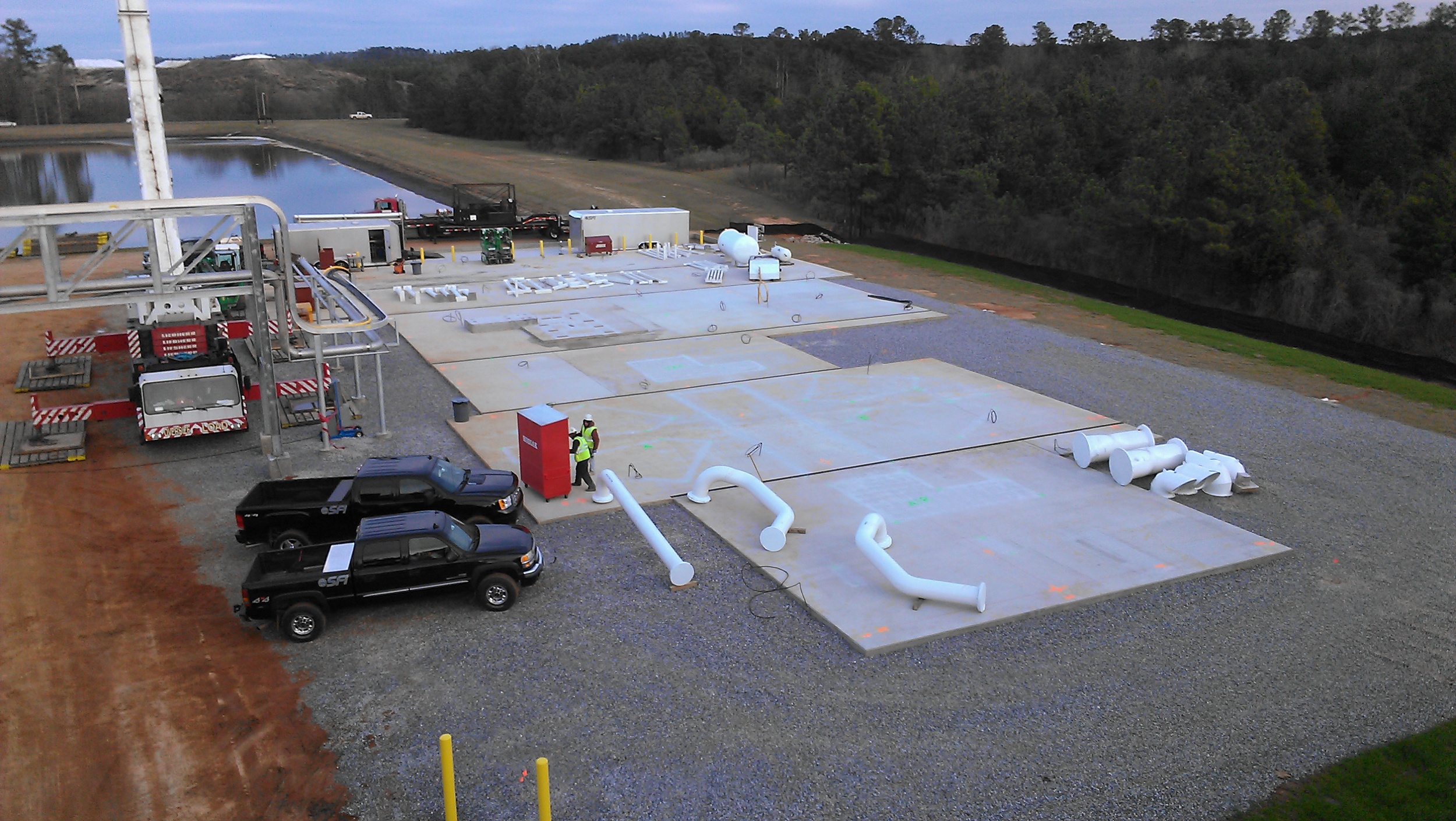

Industrial Gas Plant Installation

At Specialty Fitters, Inc., we specialize in providing top-notch industrial gas plant installation services to meet your business needs. With years of experience in the industry, our team of experts is dedicated to ensuring a seamless and efficient installation process from start to finish.

Our installation services are tailored to your specific requirements, ensuring that your industrial gas plant is installed correctly and operates at optimal levels. We understand the importance of precision and reliability in industrial settings, which is why we guarantee the highest quality workmanship and attention to detail.

By choosing Specialty Fitters Inc., you can trust that your industrial gas plant installation will be completed on time and within budget. Our commitment to excellence and customer satisfaction sets us apart as a reliable and trusted partner for all your industrial installation needs.

Our proven solutions will increase productivity and improve cost efficiency

Our services include; design and engineering, consulting, site survey, equipment counseling, price analysis, complete system installations, maintenance, inspections & certifications, system repairs and modifications, equipment supplies, site tear downs.

Our services exceed safety regulations and follow NFPA, CGA and OSHA standards.

Project Management & Turn-Key Installations

At Specialty Fitters Inc., we specialize in providing top-tier contractor project management services and turn-key gas system installations. With years of experience in the industry, our team is dedicated to delivering high-quality solutions tailored to meet your project needs.

Our contractor project management services ensure seamless coordination and execution of every aspect of your project, from planning to completion. We work closely with you to understand your requirements and goals, ensuring that we deliver results that exceed your expectations.

When it comes to gas system installations, our turn-key solutions provide you with a hassle-free experience. Our expert team handles everything from system design and engineering to installation, testing, and commissioning.

Whether you are looking to upgrade your existing gas system or undertake a new installation project, Specialty Fitters Inc. is here to help. Trust us to deliver reliable, efficient, and cost-effective solutions that meet your needs.

Consulting, System Evaluation, Cost Analysis, Mechanical Drawings, Scheduling & Planing, Safety Training, Facility Shutdown, Site Preparation, Crane/Rigging Services, Equipment Transportation & Delivery Scheduling, Fabrication, Engineering, Assembly & Installation, Electrical Services, Pipe Insulation, Labeling, Startup, Testing, Maintenance Programs, Millwright Services, Industrial Electrical Servives.

Pipe Insulation

Insulation will reduce heat loss or gain, maintain process stability, protect against fire, control condensation vermin and corrosion, reduce noise and vibrations, save energy, protect the environment and most importantly protect personnel. Depending on your project, Specialty Fitters offers insulation choices.

Fiberglass - the most common one made from molten glass spun into microfibers The insulation is molded or flexible, heavy-density, with or without factory-applied jacket. Commonly used in commercial buildings, power generation facilities, process and industrial piping applications. - Can be rigid or flexible and has a broad range of applications because of its varying thicknesses and outstanding insulating capacity. Other reasons to use polyurethane include heat stability, mechanically resistant and low water absorption.

Polyurethane - Can be rigid or flexible and has a broad range of applications because of its varying thicknesses and outstanding insulating capacity. Other reasons to use polyurethane include heat stability, mechanically resistant and low water absorption.

Foamglas (Pittsburgh Corning) - Is the ideal choice for insulating cryogenic systems. Especially low temperature equipment tanks and vessels, chemical process piping, above or underground steam and chilled piping systems.

Insulation Protection - All insulation installed by SFI will be covered and sealed. Materials used are PVC, Aluminum, or Stainless.

When you choose Specialty Fitters Inc. for your industrial piping needs, you can rest assured that you are getting a reliable, efficient, and cost-effective solution that will help you achieve your production goals. Contact us today to learn more about how our high-purity process piping systems can benefit your operation.